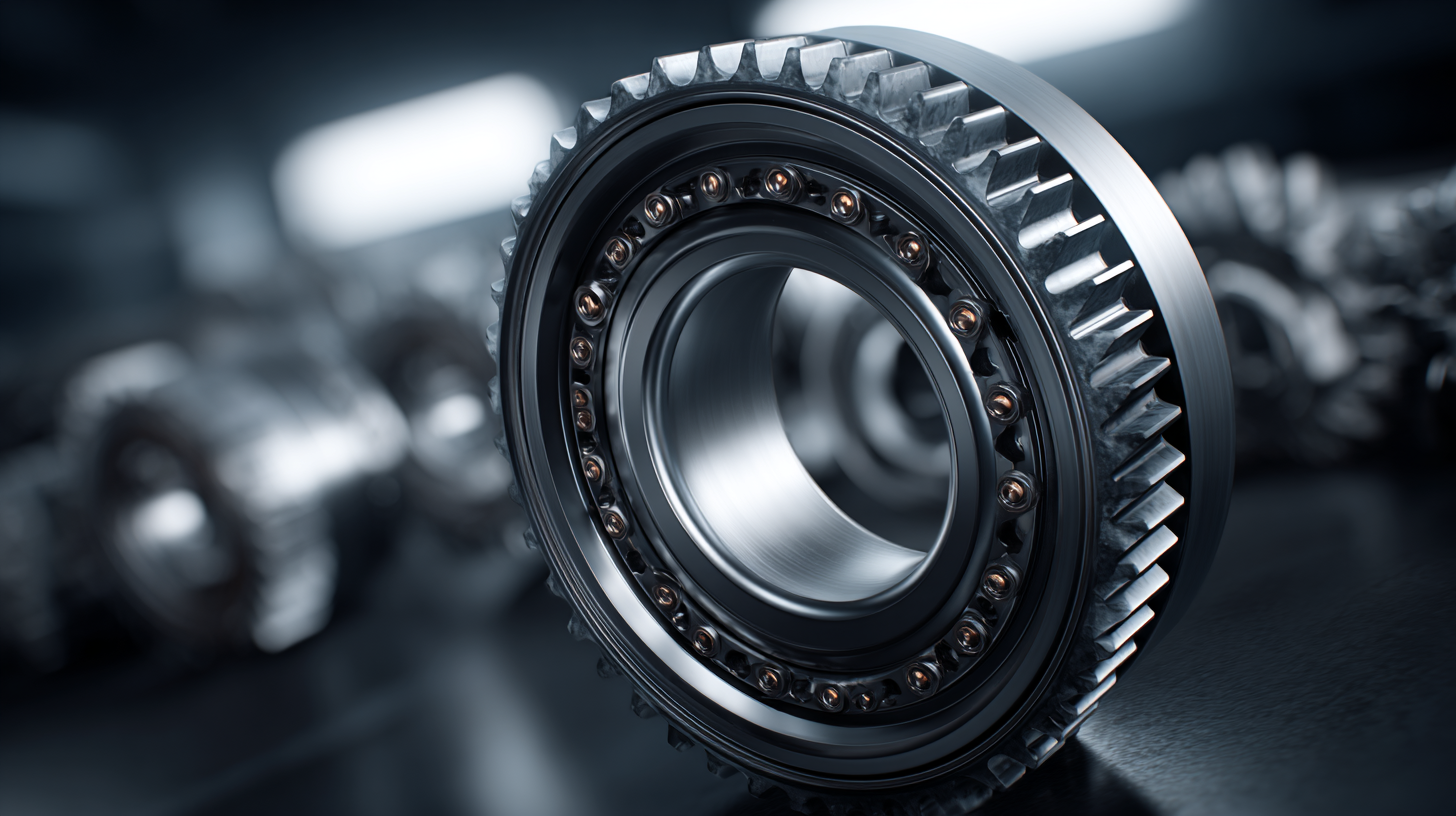

Exploring the Science of High Speed Ball Bearings: Revolutionizing Efficiency in Modern Machinery

In the ever-evolving landscape of modern machinery, high speed ball bearings have emerged as a critical component in enhancing operational efficiency and performance. According to a recent report by the International Journal of Mechanical Engineering, the demand for high speed ball bearings is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2027, driven by the increasing need for precision and reliability in various industries, including automotive and aerospace.

These sophisticated bearings minimize friction and enable smoother operation at elevated speeds, which is essential in applications ranging from turbines to electric motors. As manufacturers strive to innovate and optimize their processes, understanding the science behind high speed ball bearings will be paramount in harnessing their full potential, ultimately revolutionizing the efficiency of modern machinery and paving the way for advancements in technology and productivity.

Understanding High Speed Ball Bearings: A Key Component in Modern Technology

High speed ball bearings play a crucial role in enhancing the efficiency of modern machinery, serving as a vital component in a variety of technological applications. These bearings are designed to operate at high rotational speeds while minimizing friction and wear. According to a report by MarketsandMarkets, the global market for high-speed bearings is expected to grow from USD 15.45 billion in 2020 to USD 20.20 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.6%. This growth is largely driven by advancements in industries such as automotive, aerospace, and robotics, where precision and performance efficiency are paramount.

In high-speed applications, such as turbines and electric motors, ball bearings help reduce energy loss and enhance performance. A study from the American Society of Mechanical Engineers highlights that properly designed high-speed ball bearings can decrease operational energy costs by up to 30%. The use of advanced materials like ceramic and hybrid bearings has also shown significant improvements in performance; these materials can withstand higher speeds and temperatures, thereby extending the lifespan of machinery while maintaining optimal efficiency. This innovation not only supports increased productivity but also contributes to a more sustainable approach in manufacturing processes.

The Physics Behind High Speed Performance: Mechanics of Ball Bearings

The physics of high-speed performance in ball bearings centers on the fundamental mechanics that enable these critical components to function efficiently under extreme conditions. At the core of this performance is the design and material composition of the bearings themselves. High-speed ball bearings are typically constructed from advanced materials such as ceramic and high-grade steel, which offer superior strength and lower friction compared to conventional materials. This reduction in friction is crucial, as it directly affects the overall energy efficiency and operational longevity of the machinery they support.

In addition to material properties, the geometry and precision engineering of ball bearings play a pivotal role in their high-speed capabilities. The alignment of balls within the races is meticulously designed to minimize contact points and distribute loads evenly, reducing wear and heat generation. Furthermore, innovations like lubrication methods and sealing technologies enhance the performance of these bearings by preventing contaminants from interfering with their operation. Understanding the intricate mechanics at play allows engineers to optimize machinery design, ensuring that high-speed applications operate smoothly and effectively.

Exploring the Efficiency of High Speed Ball Bearings

Applications of High Speed Ball Bearings: Industries Benefiting from Enhanced Efficiency

High-speed ball bearings are becoming increasingly essential across various industries, offering enhanced efficiency that directly impacts machinery performance. With the global bearing market projected to reach $468.2 billion in 2024 and further expand to approximately $971 billion by 2032, the demand for high-speed ball bearings continues to surge. These components play a crucial role in modern machinery, enabling smoother operations and reducing energy losses, which is particularly vital in the context of electric vehicles and advanced manufacturing processes.

Industries such as automotive and robotics are reaping significant benefits from the advancements in high-speed ball bearing technology. As the automotive sector transitions toward electrification and automation, the need for components that can support higher speeds and efficiency is paramount. For instance, innovative designs in hybrid ceramic deep groove ball bearings have demonstrated the capability to withstand elevated speeds, thus catering to the evolving requirements of electric motors. Moreover, the bearing industry's complexity and high barriers to entry further emphasize the substantial market opportunities available for manufacturers looking to leverage these technological advancements.

Challenges and Innovations: Overcoming Limitations in High Speed Designs

The advancement of high-speed ball bearings is critical in addressing the limitations faced in modern machinery. As industries push for greater efficiency and precision, the need for innovative solutions becomes paramount. Recent developments, such as ultra-compact phased-array transceivers for 6G applications, highlight the trend towards minimizing circuit footprints while maximizing performance. This technology echoes the demands placed on high-speed designs, where reducing friction and enhancing speed are essential for optimal operation. Reports indicate that these innovations could enhance data rates beyond 150 GHz, showcasing an intersectionality of high-speed performance and compact design.

Moreover, the incorporation of two-dimensional materials into semiconductor technologies underlines how materials science can contribute to overcoming existing challenges in high-speed ball bearing designs. The exploration of multi-bridge-channel transistors illustrates a potential roadmap for improving the efficiency of electronic devices. By utilizing advanced materials such as perovskites and quantum dots, researchers aim to address thermal issues and improve overall system gain—challenges that are similarly encountered in high-speed machinery. As these sectors converge, the quest for overcoming limitations in high-speed designs becomes a beacon for future innovations, paving the way for more efficient, durable, and capable machinery in various industries.

Future Trends: The Next Generation of High Speed Ball Bearing Technologies

The future of high-speed ball bearing technology is poised for remarkable advancements that will significantly enhance machinery efficiency. As industries push for higher performance with lower energy consumption, new materials such as advanced ceramics and hybrid compounds are being developed. These materials not only provide reduced friction but also exhibit exceptional heat resistance, enabling bearings to operate at increased speeds and loads without compromising durability.

In addition to material innovations, smart technologies are emerging within the realm of ball bearings. Integrating sensors into bearing designs can facilitate real-time monitoring of performance metrics such as temperature and vibration. This will allow for predictive maintenance, reducing downtime and maintenance costs. Furthermore, the incorporation of AI and machine learning algorithms into bearing design and application will optimize their configurations for specific environments, paving the way for bespoke solutions that meet the specific demands of various industries.

As these trends continue to evolve, the landscape of high-speed ball bearings will transform, paving the way for even greater efficiency and reliability in modern machinery.