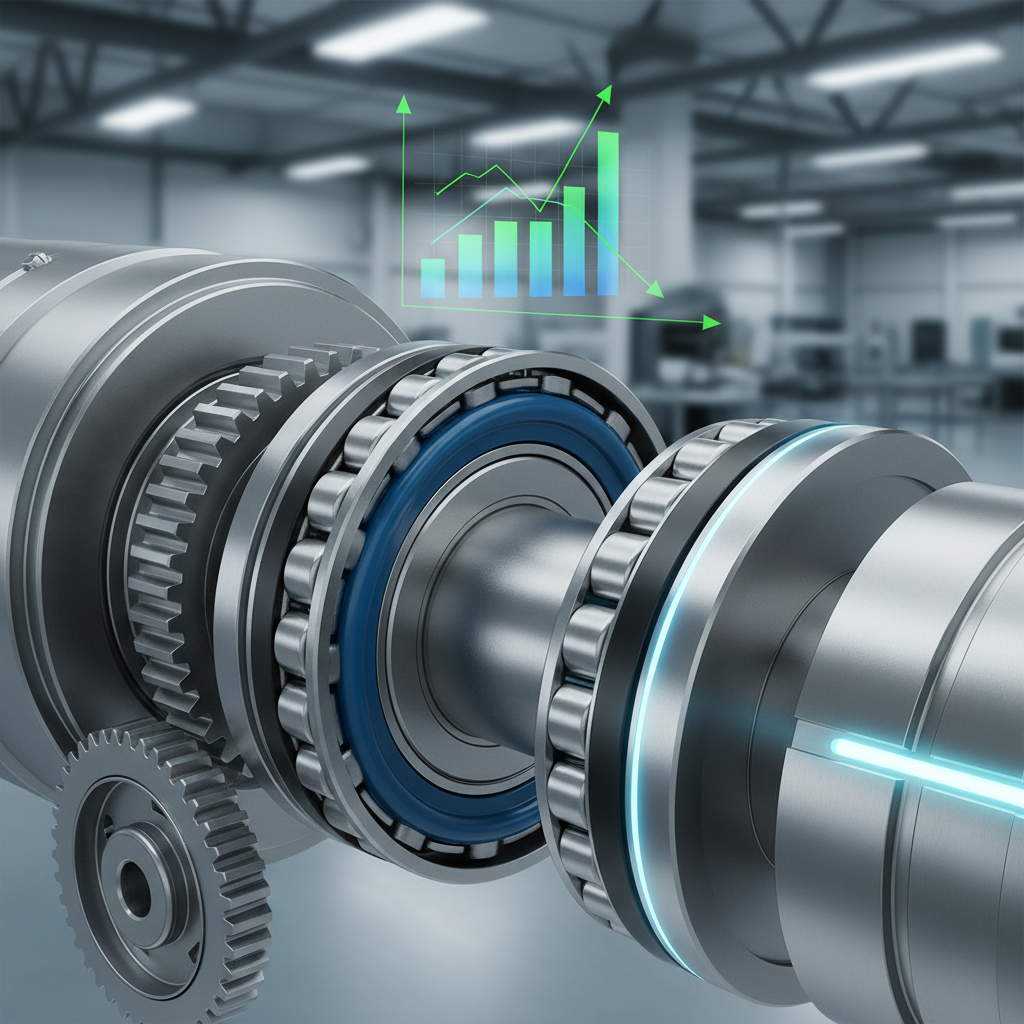

Why Sealed Roller Bearings Improve Equipment Efficiency and Longevity with 30 Percent Reduced Maintenance Costs

Sealed roller bearings have emerged as a pivotal innovation in enhancing equipment performance across various industries, boasting a remarkable 30 percent reduction in maintenance costs. According to a report by the Global Bearing Industry Association, the implementation of sealed roller bearings can lead to significant efficiency gains, with some sectors reporting up to 15 percent increases in operational uptime. This dramatic improvement is attributed to their design, which minimizes contamination and lubrication loss, extending the lifespan of machinery and reducing the need for frequent maintenance.

Industry expert Dr. James Henderson, a recognized authority in bearing technology, notes, “Sealed roller bearings represent the next evolution in mechanical reliability; their robust sealing mechanisms not only protect internal components but also facilitate smoother operations under demanding conditions.” His insights underscore the increasing reliance on sealed roller bearings in sectors ranging from manufacturing to automotive, where durability and efficiency are paramount.

As companies strive to optimize their operations and lower total costs, the transition to sealed roller bearings stands out as a strategic choice, promising reduced downtime and enhanced longevity of equipment. This shift is not just a trend but a foundational step toward building a more sustainable and efficient industrial future.

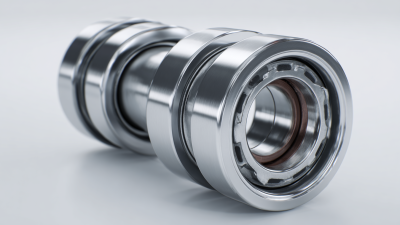

Understanding Sealed Roller Bearings and Their Design Advantages

Sealed roller bearings represent a significant advancement in bearing technology, offering distinct design advantages that enhance equipment performance. Unlike traditional open bearings, sealed roller bearings have a protective enclosure that keeps lubricants intact while preventing contaminants like dirt and moisture from entering. This design not only minimizes the likelihood of premature wear but also extends the operational lifespan of the bearings, leading to increased overall equipment efficiency.

According to a report by the American Society of Mechanical Engineers (ASME), equipment utilizing sealed roller bearings can experience a 10-15% increase in longevity when compared to open bearings.

Furthermore, the inherent efficiency of sealed roller bearings contributes to substantial reductions in maintenance costs. Industry studies indicate that enterprises can lower their maintenance expenses by as much as 30% by adopting these technologically advanced bearings. This cost reduction stems from less frequent lubrication needs and decreased downtime due to the reduced risk of bearing failure.

A survey conducted by Bearing News reveals that organizations transitioning to sealed roller bearings reported an average operational cost saving of $35,000 annually, underlining the economic benefits alongside the enhanced reliability they offer.

The Role of Seal Technology in Enhancing Bearing Performance

Sealed roller bearings represent a significant advancement in bearing technology, where the integration of seal technology plays a critical role in enhancing performance. The primary function of seals is to prevent contaminants such as dust, dirt, and moisture from entering the bearing assembly. This protective barrier not only prolongs the life of the lubricant but also minimizes wear and tear on the bearing surfaces, which is essential for maintaining operational efficiency. By keeping contaminants at bay, sealed roller bearings ensure smoother operation and reduce the frequency of maintenance interventions.

Sealed roller bearings represent a significant advancement in bearing technology, where the integration of seal technology plays a critical role in enhancing performance. The primary function of seals is to prevent contaminants such as dust, dirt, and moisture from entering the bearing assembly. This protective barrier not only prolongs the life of the lubricant but also minimizes wear and tear on the bearing surfaces, which is essential for maintaining operational efficiency. By keeping contaminants at bay, sealed roller bearings ensure smoother operation and reduce the frequency of maintenance interventions.

Moreover, the use of advanced sealing materials has improved the durability and reliability of these bearings under various operating conditions. Unlike traditional bearings, which may require regular lubrication and maintenance, sealed roller bearings can operate effectively over extended periods without needing frequent upkeep. This reduced maintenance requirement leads to cost savings—estimated at up to 30 percent—while also increasing equipment uptime. As industries continue to prioritize efficiency and longevity, the role of seal technology in roller bearings will remain vital, making it a crucial consideration for manufacturers seeking to enhance their equipment's performance.

Comparative Analysis: Sealed vs. Open Bearings in Equipment Efficiency

Sealed roller bearings have emerged as a superior choice for enhancing equipment efficiency compared to traditional open bearings. A comparative analysis reveals that sealed bearings minimize contaminant ingress, which accounts for about 80% of bearing failures according to data from the National Lubricating Grease Institute (NLGI). This reduction in contamination significantly extends the life cycle of the bearings and, consequently, the machinery they support. In industries such as manufacturing and construction, where operational downtime can result in substantial financial losses, the advantages of sealed roller bearings become even more pronounced.

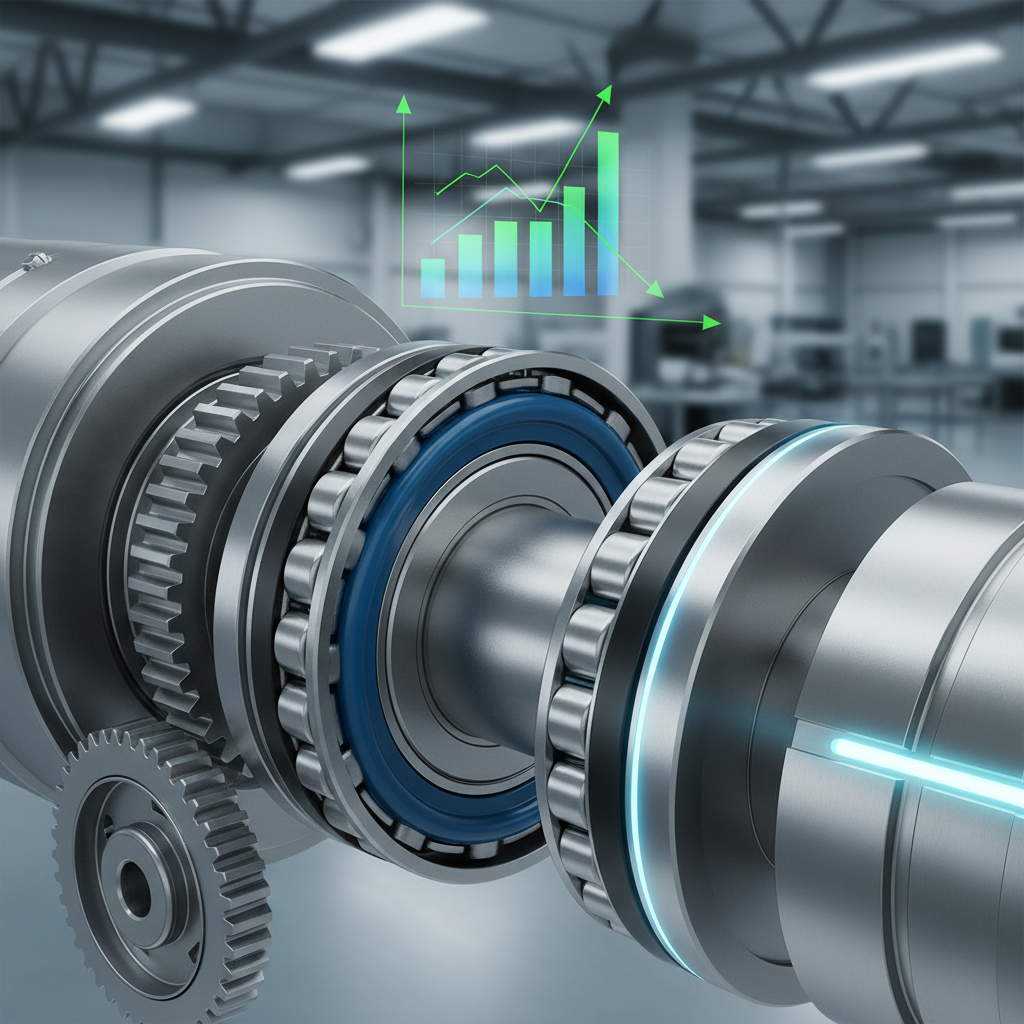

Additionally, studies show that sealed bearings can lead to a reduction in maintenance costs by approximately 30%. This is primarily due to decreased frequency of replacements and maintenance interventions—as they preserve lubrication more effectively in environments that challenge open bearings. Reports from the American Bearing Manufacturers Association (ABMA) indicate that businesses utilizing sealed roller bearings have experienced increased overall equipment effectiveness (OEE) by up to 20%, emphasizing their role in not only reducing costs but also boosting productivity and operational reliability. The data underscores how a seemingly simple design choice can lead to substantial improvements in both efficiency and longevity, making sealed roller bearings a critical consideration for equipment designers and operators alike.

Quantifying Maintenance Cost Savings with Sealed Roller Bearings

Sealed roller bearings have emerged as a game-changer in the realm of equipment efficiency and maintenance cost reduction. Recent industry studies reveal that the implementation of sealed roller bearings can lead to up to 30 percent savings in maintenance costs. By eliminating the need for frequent re-lubrication and reducing contaminants entering the bearing, these solutions significantly upgrade the reliability and lifespan of machinery. A report from a leading maintenance technology firm indicates that organizations utilizing sealed roller bearings can expect an average increase in equipment longevity by 40 percent, translating into fewer repair cycles and less downtime.

Moreover, the quantifiable benefits of sealed roller bearings extend beyond maintenance savings. For instance, research into friction levels across various bearing types shows that sealed roller bearings consistently demonstrate lower drag coefficients. This reduction in friction not only enhances performance but also contributes to improved energy efficiency. One study highlighted that machinery with sealed roller bearings operated at a 15 percent lower energy cost compared to traditional bearings. Overall, the transition to sealed roller bearings stands as a highly effective strategy for businesses aiming to maximize operational efficiency while minimizing associated maintenance expenditures.

Long-Term Benefits: Longevity and Reliability of Sealed Roller Bearings

Sealed roller bearings have emerged as a game-changer in the realm of equipment longevity and reliability, particularly within the construction sector. With their innovative designs, these bearings significantly mitigate exposure to contaminants, which is crucial in harsh operational environments.

Studies have indicated that the use of sealed roller bearings can reduce maintenance costs by up to 30%, while also extending the life span of machinery components. This translates to improved operational efficiency, allowing equipment to deliver peak performance over extended periods.

Moreover, advancements in sealing technology, such as diamond-coated mechanical seals, have further fortified the protective capabilities of these bearings. This innovation not only reduces the likelihood of equipment breakdowns but also enhances overall reliability.

In a sector where uptime is paramount, the durability offered by sealed roller bearings is invaluable. Reports suggest that machinery equipped with these bearings can operate effectively for thousands of hours longer than those with traditional bearings, emphasizing their role in sustaining productivity and reducing lifecycle costs in the long run.

Sealed roller bearings represent a significant advancement in bearing technology, where the integration of seal technology plays a critical role in enhancing performance. The primary function of seals is to prevent contaminants such as dust, dirt, and moisture from entering the bearing assembly. This protective barrier not only prolongs the life of the lubricant but also minimizes wear and tear on the bearing surfaces, which is essential for maintaining operational efficiency. By keeping contaminants at bay, sealed roller bearings ensure smoother operation and reduce the frequency of maintenance interventions.

Sealed roller bearings represent a significant advancement in bearing technology, where the integration of seal technology plays a critical role in enhancing performance. The primary function of seals is to prevent contaminants such as dust, dirt, and moisture from entering the bearing assembly. This protective barrier not only prolongs the life of the lubricant but also minimizes wear and tear on the bearing surfaces, which is essential for maintaining operational efficiency. By keeping contaminants at bay, sealed roller bearings ensure smoother operation and reduce the frequency of maintenance interventions.