The Ultimate Guide to Understanding Sealed Roller Bearings: Features, Benefits, and Applications

In an era where efficiency and reliability are paramount, sealed roller bearings have emerged as critical components in various industries, optimizing performance and prolonging equipment lifespan. According to a recent report by Markets and Markets, the global bearing market is projected to grow from $73.22 billion in 2021 to $90.55 billion by 2026, driven largely by advancements in bearing technologies such as sealed roller bearings. These innovative bearings offer superior protection against contaminants and reduce maintenance frequency, making them ideal for applications in automotive, aerospace, and industrial machinery. As industries evolve, the demand for sealed roller bearings continues to rise, underscoring their vital role in enhancing operational efficiency and reducing costs. This guide aims to delve into the features, benefits, and various applications of sealed roller bearings, providing a comprehensive understanding for engineers and decision-makers alike.

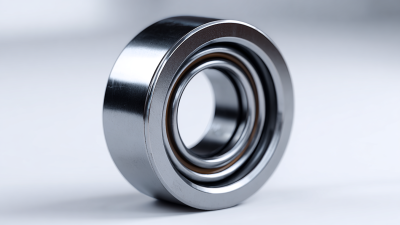

Understanding the Structure and Functionality of Sealed Roller Bearings

Sealed roller bearings are critical components in various mechanical systems, expertly designed to reduce friction and improve efficiency. Understanding their structure and functionality is essential for optimizing performance in applications ranging from automotive to industrial machinery. A sealed roller bearing typically consists of inner and outer rings with cylindrical or spherical rollers in between, all encased in a durable seal. This design not only minimizes the intrusion of contaminants but also retains lubricants, ensuring smoother operation and increased lifespan.

The functionality of sealed roller bearings is enhanced by their specialized seals and materials. The seals effectively prevent dust, dirt, and moisture from entering the bearing, which could lead to premature wear and failure. Additionally, the choice of materials for both the bearing elements and the seals contributes to their heat resistance and load-bearing capabilities, making them suitable for high-performance applications. Understanding how these features work together helps users select the right bearings for their specific needs, ensuring greater efficiency and reliability in their operations.

The Ultimate Guide to Understanding Sealed Roller Bearings

Key Features of Sealed Roller Bearings That Enhance Performance

Sealed roller bearings are engineered with integral seals that play a crucial role in enhancing their performance and longevity in a variety of applications. These seals, typically made from high-quality elastomers, provide a barrier against contaminants such as dust, dirt, and moisture. According to a recent report by the International Journal of Engineering and Technology, using sealed bearings can reduce maintenance costs by up to 30% due to their ability to retain lubricants longer and minimize wear and tear on moving parts. This is particularly beneficial in industries such as automotive, aerospace, and heavy machinery, where reliability is paramount.

Additionally, sealed roller bearings offer improved operational efficiency. With less friction and better alignment, these bearings enable higher speeds and lower energy consumption in rotating equipment. The American Society of Mechanical Engineers (ASME) has reported that implementing sealed bearings can lead to energy savings of 15-25%, making them an attractive option for modern machinery. Their effective sealing technology contributes to consistent performance in challenging environments, thus extending the overall service life of the bearings and equipment they support.

Advantages of Using Sealed Roller Bearings in Various Industries

Sealed roller bearings have gained significant traction in various industries due to their distinct advantages. One of the primary benefits is their ability to minimize contamination, which is crucial for ensuring the longevity and reliability of machinery. By preventing dirt, dust, and moisture from entering the bearing, these sealed solutions greatly enhance operational effectiveness. This feature is particularly valuable in environments exposed to harsh conditions, such as manufacturing facilities and construction sites.

Moreover, the economic implications of utilizing sealed roller bearings cannot be overlooked. High-quality sealed bearings contribute to reduced maintenance requirements and lower operational costs. The cost savings associated with decreased downtime can be substantial, especially when considering the staggering expenses linked to unplanned work stoppages. As industries increasingly prioritize efficiency, the demand for sealed roller bearings is expected to rise, reflecting the broader growth trend anticipated in the global bearings market. Their continued adoption across sectors not only improves productivity but also aligns with the goals of sustainability and operational excellence.

Common Applications of Sealed Roller Bearings: Where Are They Used?

Sealed roller bearings are widely used in various industries due to their exceptional performance and durability. Common applications include automotive systems, industrial machinery, and consumer electronics. According to a market report by Grand View Research, the global bearing market is projected to reach USD 202.6 billion by 2025, driven largely by the increasing demand for sealed roller bearings in sectors such as aerospace and automotive. These bearings are particularly favored in applications that require reduced maintenance and longer service life, such as in electric motors and conveyor systems.

In the automotive sector, sealed roller bearings play a crucial role in enhancing fuel efficiency by minimizing friction and wear. A study by the Society of Automotive Engineers (SAE) indicated that using high-performance sealed bearings can improve the overall efficiency of vehicles by up to 3%. Meanwhile, in industrial applications, these bearings help maintain optimal performance in harsh environments, significantly reducing the risk of contamination and downtime. With the continued evolution of technology, the demand for sealed roller bearings in robotics and automation is also on the rise, emphasizing their versatility across various fields.

Maintenance Tips for Maximizing the Lifespan of Sealed Roller Bearings

When it comes to maximizing the lifespan of sealed roller bearings, proper maintenance is essential. Sealed roller bearings are designed to offer superior protection against dirt and moisture, thanks to their robust seals. However, regular inspections and appropriate lubrication can further enhance their longevity. Ensure that you clean the bearing housing periodically to prevent the buildup of contaminants that can compromise performance. Additionally, using the right type of lubricant is crucial; consult the manufacturer's specifications to choose a lubricant that best suits the operating conditions of the bearing.

Moreover, understanding the specific application of your sealed roller bearings can also inform better maintenance practices. For instance, in high-load environments, bearings may experience increased friction and heat. To counteract potential wear, it's advisable to monitor bearing temperature closely and replace them when necessary. Innovations in sealed roller bearing technology, such as enhanced sealing mechanisms that thwart contamination, also contribute to prolonged service life. Being proactive about maintenance not only saves costs associated with replacements but also ensures that equipment operates at peak efficiency, preventing unexpected breakdowns that can disrupt operations.