The Ultimate Guide to Understanding and Choosing Flanged Thrust Bearings for Optimal Performance

In the world of industrial machinery, the importance of selecting the right components cannot be overstated, particularly when it comes to flanged thrust bearings. According to a comprehensive market analysis by Research and Markets, the global market for advanced bearing technologies is expected to grow significantly, reflecting an increased demand for high-performance solutions in various applications. Flanged thrust bearings, known for their ability to manage axial loads with precision, play a crucial role in enhancing the efficiency and longevity of machinery. As industries strive for optimization and reliability, understanding the intricacies of flanged thrust bearings becomes essential. This guide aims to provide valuable insights into their functionality, selection criteria, and impact on operational performance, empowering engineers and procurement professionals to make informed decisions that lead to optimal outcomes.

Types of Flanged Thrust Bearings: A Comprehensive Overview

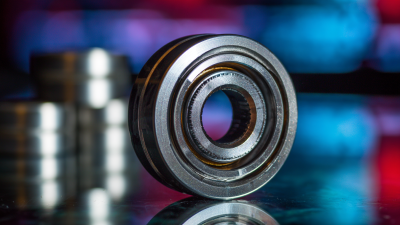

When selecting flanged thrust bearings, understanding the various types available is crucial for achieving optimal performance in your application. Flanged thrust bearings are designed to handle axial loads while providing reliable rotation, making them ideal for applications that require robust support. The two most common types are ball thrust bearings and roller thrust bearings, each offering distinct advantages depending on your operational needs.

When selecting flanged thrust bearings, understanding the various types available is crucial for achieving optimal performance in your application. Flanged thrust bearings are designed to handle axial loads while providing reliable rotation, making them ideal for applications that require robust support. The two most common types are ball thrust bearings and roller thrust bearings, each offering distinct advantages depending on your operational needs.

Ball thrust bearings, characterized by their use of balls between the races, are known for their high-speed capabilities and low friction. This type is often preferred in applications where smooth operation and speed are essential, such as in electric motors and agricultural machinery. On the other hand, roller thrust bearings feature cylindrical rollers that provide a larger contact area, allowing them to support heavier loads and withstand shock loading better. They are commonly found in industrial machinery and gear systems, where durability and load-bearing capacity are paramount.

Choosing the right type of flanged thrust bearing is critical for ensuring reliability and efficiency. By understanding the differences between ball and roller thrust bearings, as well as their specific applications, engineers and technicians can make informed decisions that enhance the performance and longevity of their machinery.

Key Features and Specifications of Flanged Thrust Bearings

Flanged thrust bearings are crucial components in various machinery applications, providing support for axial loads while ensuring smooth rotational movement. Understanding their key features and specifications is essential for optimal performance. These bearings typically consist of a flat or flanged outer surface that provides stability and facilitates proper alignment. According to a recent industry report by the American Bearing Manufacturers Association (ABMA), the selection of materials, such as bearing steel or composite materials, significantly affects durability and resistance to wear, enhancing the lifespan of the bearing.

When evaluating flanged thrust bearings, consider the load capacity, which is often measured in pounds or kilograms. It's essential to match the bearing's load ratings with your application's requirements to prevent premature failure. Additionally, compatibility with lubricants should not be overlooked, as proper lubrication reduces friction and heat generation. A report from the International Journal of Engineering Research highlights that improper lubrication can lead to a reduction in bearing life by up to 50%.

Tips: Always check the maximum allowable axial load and ensure that the bearing's outer diameter does not exceed the design specifications of your equipment. Regular maintenance and monitoring for signs of wear can help extend the life of your flanged thrust bearings, thus ensuring continual optimal performance.

Applications of Flanged Thrust Bearings in Various Industries

Flanged thrust bearings play a crucial role across various industries, particularly in automotive applications. These bearings are designed to handle axial loads, making them essential components in vehicle systems where stability and reliability are paramount. With an increasing focus on performance and efficiency in the automotive sector, manufacturers utilize flanged thrust bearings to ensure smooth operation in gearboxes, clutches, and other critical assemblies. Their unique design allows for effective load distribution and minimizes wear, thus enhancing the longevity of mechanical systems.

In addition to automotive uses, flanged thrust bearings find applications in machinery, aerospace, and heavy equipment industries. In industrial settings, these bearings support rotating components and enable precise movement, essential for maintaining operational integrity in manufacturing processes. The versatility of flanged thrust bearings makes them a preferred choice for both standard and custom applications, responding to the growing demands for performance and durability in various sectors. As the global market for automotive bearings is set to expand significantly, the role of flanged thrust bearings will only become more vital in ensuring optimal performance across multiple applications.

The Applications of Flanged Thrust Bearings Across Different Industries

Factors to Consider When Choosing Flanged Thrust Bearings

When selecting flanged thrust bearings, there are several critical factors to consider to ensure optimal performance in your application. First and foremost, load capacity is paramount; bearings must be chosen based on the expected axial loads they will encounter. This requires a careful assessment of the maximum load conditions to ensure that the bearing can endure the stresses without failure. Additionally, examining the dynamic and static load ratings provided by manufacturers will help you make an informed decision.

Another important factor is the material of the bearing itself. Flanged thrust bearings are available in various materials, including steel, bronze, and composite materials. Each material has its own advantages and limitations, such as resistance to corrosion, wear rates, and thermal conductivity. Your choice should align with the operational environment and specific requirements of your machinery. Furthermore, consider the lubrication options available for the bearings, as proper lubrication can significantly enhance both the efficiency and lifespan of the bearings, reducing maintenance needs and downtime in the process.

Finally, the installation configuration is crucial. Ensuring the correct alignment and fitment of flanged thrust bearings will prevent premature wear and ensure smoother operation. Pay close attention to the dimensions of the mounting surfaces and the compatibility with your machinery to guarantee a seamless integration. Taking these factors into account will help you choose the right flanged thrust bearings tailored for your specific needs.

The Ultimate Guide to Understanding and Choosing Flanged Thrust Bearings for Optimal Performance

| Bearing Type |

Load Capacity (kN) |

Speed Rating (RPM) |

Material |

Lubrication Type |

| Single-direction Thrust Bearing |

30 |

1500 |

Steel |

Grease |

| Double-direction Thrust Bearing |

40 |

1200 |

Stainless Steel |

Oil |

| Tapered Roller Thrust Bearing |

50 |

1000 |

Bronze |

Grease |

| Spherical Thrust Bearing |

35 |

1400 |

Carbon Steel |

Oil |

| Cylindrical Thrust Bearing |

45 |

1600 |

Alloy Steel |

Grease |

Maintenance Tips for Enhancing the Lifespan of Thrust Bearings

Flanged thrust bearings are critical components that require proper maintenance to ensure optimal performance and extended lifespan. One of the most essential maintenance tips is regular lubrication. Adequate lubrication reduces friction and wear between the bearing surfaces, allowing for smoother operation. It is crucial to use the correct type of lubricant recommended by the manufacturer to ensure efficient performance. Be sure to check the lubricant levels frequently and replenish them as needed, especially in high-load or high-temperature environments.

Another vital aspect of maintenance is periodic inspection. Regularly inspecting the flanged thrust bearings can help identify potential issues before they lead to significant failures. Look for signs of wear, such as discoloration or pitting, and check for any unusual noises during operation that may indicate misalignment or contamination. Additionally, ensuring that the surrounding equipment is clean and free from debris can prevent harmful particles from entering the bearing and causing damage. By incorporating these maintenance practices, users can enhance the lifespan and reliability of their thrust bearings, ultimately leading to improved machine performance.

When selecting flanged thrust bearings, understanding the various types available is crucial for achieving optimal performance in your application. Flanged thrust bearings are designed to handle axial loads while providing reliable rotation, making them ideal for applications that require robust support. The two most common types are ball thrust bearings and roller thrust bearings, each offering distinct advantages depending on your operational needs.

When selecting flanged thrust bearings, understanding the various types available is crucial for achieving optimal performance in your application. Flanged thrust bearings are designed to handle axial loads while providing reliable rotation, making them ideal for applications that require robust support. The two most common types are ball thrust bearings and roller thrust bearings, each offering distinct advantages depending on your operational needs.